Custom manufacturing of Intermediates, APIs, Excipients and Polymers for drug delivery solutions

PMC Isochem offers cGMP and non cGMP industrial exclusive custom synthesis and provides tailor made services from development to production, including route selection, process and analytical development as well as process optimization.

Flexible Solutions: PMC Isochem's highly skilled teams interact closely with the pilot units and multipurpose facilities.

Reduced Time to Market: PMC Isochem's knowledge and management tools ensure an optimized timing for projects.

Continuous Cost Savings: PMC Isochem delivers substantial improvements in manufacturing and creates additional value by reducing operating costs.

Security of Supply Chain: PMC Isochem optimizes and secures sourcing of raw materials, based on total transparency with customers.

Custom manufacturing of APIs, GMP Excipients, Polymers for drug formulation like polyaminoacid (Poly-Sarcosine, Poly-Lysine, Poly-Glutamic acid or esters, Poly-Leucine, and many copolymers), Polymer drug conjugates

- cGMP (FDA) and non cGMP

- Clinical batch supply

- Routine production

- Supply chain

- Regulatory support

- Risk management

- Full transparency

Case studies

Preclinical and tox studies of an NCE

- Minimum R&D for secured scale-up from medicinal chemistry

- Solving a major stability issue of an intermediate

- Rapid roduction of 3 kg batch

Phase I advanced intermediate: 100 kg delivery

Achievement: development and scale-up from lab procedure

- Rapid development (avoiding 2 filtrations & use of DCM)

- Minimum R&D for secured scale-up

- Production of 100 kg batch 4 months after kick-off

- Then development and scale-up of a second generation process

Pre-launch regulated intermediate: multiton production

Achievement: Rapid industrial technical transfer

- Demonstration run completed 3 months after the kick-off

- Full size batch production 4 months after the kick-off

- Product quality – Supply chain & QA support

- Yield and production improvement over the following 12 months

Generic API: new supplier

Achievement: development and filing of API

- Process developed from scratch (2 steps)

- Analytical development and validation in addition to Pharmacopoeia

(GTI’s and residual solvents)

- Scale-up and process validation achieved within 9 months

- Full filing data delivered to the customer in time

Tolling hydrogenation of an intermediate

Achievement: rapid tech transfer and production

- Familiarization and scale-up preparation within 1 month

- 2 successful batches the next month

- 10 MT campaigns routinely

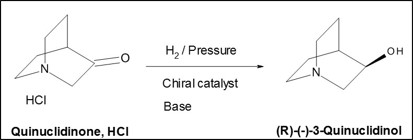

Devlopment and scale up of an catalogue molecule

(R)-(-)-3-Quinuclidinol is a leading example of our catalogue offer, the result of successful development and scale-up of a performing chiral process using a catalyst developed in a partnership.

For more detailed technical support, please contact us